1. liquid crystal

1.1. What is LCD

We all know that matter has three states: solid, liquid and gas. These three states can also be called solid phase, liquid phase, and gas phase. Most substances in nature present solid, liquid and gaseous states with temperature changes. Like water, salt, and substances made up of every element in the periodic table. Its constituent units, such as water molecules or silicon atoms, are basically like small balls. As the temperature decreases or the temperature increases, the arrangement of the constituent units changes from a subsequent disordered arrangement to a neat and orderly arrangement. That is, from liquid phase to gas phase or solid phase. In crystals, the orderly arrangement of constituent units means that each constituent unit is in a certain position, not easy to flow and arranged regularly. As long as people know its arrangement rules, they can start from a constituent unit and find them according to the law. Another unit, strict spatial ordering. In addition to the solid state, liquid state, and solid state that we know, some substances, in the process of changing from solid state to liquid state, do not directly change from solid state to liquid state, but give an intermediate state. A substance in an intermediate state that appears to be a cloudy liquid in appearance. But its optical properties and certain electrical properties are similar to crystals.

Is anisotropic, such as birefringence characteristics. As the temperature rises, various turbid substances will become clear and homogeneous liquids as the temperature rises. Conversely, when such substances change from liquid to solid, they also go through an intermediate state. All kinds of substances that can have both liquid and crystal in a certain temperature range are called Liquid Crystal, also known as liquid crystal phase, mesophase or intermediary phase, also known as the fourth state of matter.

1.2. Origin of liquid crystal

Liquid crystals were first discovered in 1888 by the Austrian botanist F. Reinitzer. When measuring the melting point of certain substances, it is found that certain substances (benzoate and ester esters of liposterols) will pass through an opaque white turbid liquid state after melting and emit colorful and beautiful luster. Will become a clear liquid. In 1889, German physicist O. Lehmann observed these lipid compounds with a polarizing microscope with a heating device designed by him at that time. He found that this kind of white turbid substance looks like liquid in appearance. However, it exhibits birefringence characteristic of anisotropic crystals. So Lehmann named it "liquid crystal". This is the origin of LCD.

For details, please refer to this article : How Was Liquid Crystal Display Invented? The Evolution History of Screen Display Technology

1.3. Types of LCD:

With the development of science and the improvement of people's understanding, it is found that liquid crystal substances are basically organic compounds. One in every 200 existing organic compounds exhibits a liquid crystal phase. From the perspective of composition and physical conditions for the appearance of liquid crystal phases, liquid crystals can be divided into two categories: thermotropic liquid crystals and lyotropic liquid crystals. When some organic substances are heated and dissolved, liquid crystals are formed due to the destruction of the crystal lattice by heating, which is called thermotropic liquid crystals, that is, some substances appear liquid crystal phases due to heating as mentioned in the previous few. Similarly, some organic substances are placed in a certain solvent, and the liquid crystal formed because the solvent destroys the crystal lattice is called a solute liquid crystal. It is a liquid crystal phase that appears due to changes in solution concentration. The most common are soapy water and so on. Currently, most of the display materials are thermotropic liquid crystals. So far, more than 20,000 kinds of liquid crystals have been discovered.

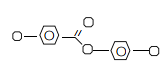

Among the numerous liquid crystals, the most studied liquid crystal is the unit liquid crystal composed of simple rod-shaped organic molecules, which are most widely used in display technology. All kinds of molecules usually have the structure shown in Figure (1): the molecule The rigid core is composed of two benzene rings and a functional group in the middle, and there are softer alkyl groups or other softer organic molecular chains at both ends of the core. As shown in Figure (1), there is an epoxy in a melting chain The resin structure makes the molecule a chiral molecule.

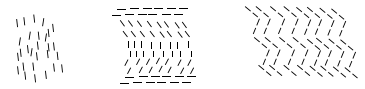

According to the different arrangements of liquid crystal molecules, they can be divided into three categories: nematic liquid crystals, cholesteric liquid crystals and smectic liquid crystals.

Figure (1)

1.3.1 Nematic liquid crystal:

The center of gravity of the molecular species of nematic liquid crystal is chaotic and disordered, so that it can flow like ordinary liquid, but the directors of the molecular rods are roughly the same, as shown in Figure (2)

1.3.2 Cholesteric liquid crystal:

In cholesteric liquid crystals, the arrangement of the centers of gravity of the molecules is disordered, but the orientation of the molecules

A vector points roughly in one direction in a plane. in a direction perpendicular to this plane. The director of the molecule will rotate to form a helical structure, as shown in Figure (3):

1.3.3 Smectic liquid crystal:

In smectic liquid crystals, the molecules form a layer-by-layer structure. The thickness of the molecular layer is about the length of one molecule. The molecules are arranged perpendicular to the plane of the molecular layer, and the center of gravity of the molecules is disordered in the molecular layer, forming a layer-by-layer two-dimensional fluid. As shown in the picture (4)

Figure(2)(3)(4)

In summary, liquid crystals can be roughly divided into the above three categories. Various types of liquid crystals have different physical properties due to their different structures. Due to the special stable temperature range of the liquid crystal material with thermotropic anisotropy above room temperature. Only this type of liquid crystal can be used as a display material.The crystal structure is so strong that it is easily affected by external influences such as electric fields, magnetic fields, temperature stress, and adsorbed impurities. Therefore, it is easy to change its optical properties. This weak molecular arrangement of liquid crystals is the key condition for liquid crystals to have a broad market today.

2. LCD Monitor

Liquid crystal has a fixed dipole moment, so applying an electric field can move the axis of liquid crystal molecules, and then the arrangement of liquid crystal molecules will change. Thereby changing its optical properties to achieve its display effect. This is the basic principle of liquid crystal as a display.

2.1. What is LCD display:

Using the various electro-optical effects of liquid crystals, changes in boundary conditions such as electric field, magnetic field, light, and temperature can be converted into visual signals under certain conditions. This is called a liquid crystal display, which is usually represented by LCD. Liquid crystal was first used in the manufacture of displays by RCA Corporation in the United States in May 1968, and has been widely used in household, industrial, and military display fields such as clocks and watches, calculators, instrumentation, laptops, mobile phones, pagers, electronic pets, pocket color televisions, large flat panel displays, and projection televisions.

2.2. Advantages and disadvantages of liquid crystal display:

Information display technology is becoming increasingly important with the development of information socialization, and liquid crystal displays have many advantages compared to other displays; Flat display, small size, light weight, easy to carry;Low power consumption and low driving voltage;Long service life, generally more than 50,000 hours;Does not contain harmful rays and is harmless to the human body;Passive display, not easy to be washed by strong light;Easy to drive, can be directly driven by large-scale integrated circuits;Simple structure, no complicated mechanical parts;Low construction cost.

With the wide application of liquid crystal display, people can also find some disadvantages:Since it is a passive component and does not emit light, it needs to rely on other light sources to be visible in the dark; There are limited viewing angles;The response speed (30ms-120ms) is not as good as other components;life has not been able to become a semi-permanent component.

3. LCD classification

3.1 There are many types of liquid crystal displays, which can be divided into transmissive and reflective direct-view and projection displays according to the display method.

3.1.1 The north side of the transmissive LCD is equipped with fluorescent lamps, electroluminescent electrodes and other light sources. Therefore, it can also be used in dim ambient light.

3.1.2 The reflective type is a kind of aluminum foil light reflective sheet attached to the outside of the glass substrate on the back of the LCD to reflect the incident light of the LCD for display. In the TN and STN modes, a polarizer and a wrinkled reflector are attached to the rear glass substrate. This reflective type takes full advantage of the low power consumption of non-luminous LCDs.

3.2 LCDs produced by photoelectric effect are roughly divided into the following types: TN-LCD, STN-LCD, HTN-LCD, FSTN-LCD, and TFT-LCD.

3.2.1 TN-LCD is a twisted nematic liquid crystal display. We all know that liquid crystal molecules are basically parallel to the base plate arrangement, but the orientation of the upper and lower liquid crystal molecules is twisted, and the overall twist is 900, TN-LCD is the earliest, most widely used, largest and cheapest display. The manufacturing process of TN-LCD is basically mature, and currently it is mainly produced in Singapore, Taiwan, mainland China and other regions. Now China is the main production base of TN-LCD. The LCDs we usually see in electronic watches, calculators, game consoles, etc. are mostly TN-LCD.

3.2.2 STN-LCD is the abbreviation of Super Twist Liquid Crystal Display. That is, super twisted nematic LCD. It is similar to TN-LCD in structure, the difference is that its twist angle is not 90°, but between 180~270, although it is only the twist angle, its working principle is completely different from that of TN-LCD. STN-LCD is a mid-range product in current LCD production. It has the characteristics of displaying more information than TN-LCD, and it is mainly used in various instruments, Chinese display machines, notepads, notebook computers, etc. The manufacturing process of STN-LCD is basically mature, but the main technology is in the hands of a few countries such as Japan and South Korea. There are more than ten STN-LCD manufacturing companies in China.

3.2.3 HTN-LCD is the abbreviation of Hight Twist Nematic Liquid Crystal Display. That is, a highly twisted nematic liquid crystal display. HTN-LCD is similar in structure to TN-LCD and STN-LCD. It's just that the twist angle of HTN-LCD is 100°~120°, between TN-LCD and STN-LCD. There are not many HTN-LCDs currently, and their performance is between TN-LCD and STN-LCD.

3.2.4 FSTN-LCD is the abbreviation of Film Super Twist Nematic Liquid Crystal Display. This is Film refers to the compensation film or retardation film, so FSTN-LCD is called the compensation film super twisted nematic liquid crystal display. The disadvantages of STN-LCD can be overcome by a specially treated compensation film.

3.2.5 TFT-LCD is an active matrix LCD with thin film transistors, which is the highest-grade product in the current LCD market. It is mainly used in notebook computers, LCD TVs, etc. The manufacturing process of TFT-LCD is relatively complicated and the price is relatively high. At present, Japan and South Korea are relatively mature countries in the world for producing TFT-LCD. In my country, only Jilin Province plans to invest in TFT-LCD production lines.

4. The structure, working principle and main technical indicators of LCD (take TN-LCD as an example).

4.1 LCD structure

① Polarizer; ② Substrate glass; ③ SIO2 barrier layer; ④ Electrode; ⑤ Orientation film; ⑥ Sealing frame; ⑦ Transition electrode; ⑧ Liquid crystal;

4.2 Working principle of LCD:

To understand how LCDs work, we first need to understand light. This is an electromagnetic wave. That is, the electromagnetic field propagates in the form of waves. The wavelength range of light visible to the human eye is roughly between 380 nanometers and 780 nanometers.

Usually light propagates along a straight line, and the vibration direction of light waves is perpendicular to the direction of light propagation. For natural light (such as sunlight), in each plane perpendicular to the direction of light propagation, the vibration directions of light waves are randomly and uniformly distributed.

If the direction of light wave vibration is along one direction, such light is called polarized light, and this vibration direction is called polarization direction. The plane formed by the polarization direction and the propagation direction of the light wave is called the vibration plane.

Polarizers have a fixed polarization axis. The function of the polarizer is to only allow the light whose vibration direction is consistent with the direction of its polarization axis to pass through. Light whose vibration direction is perpendicular to the polarization axis will be absorbed by it. In this way, when the natural light passes through the incident polarizer of the liquid crystal cell (called its polarizer), only the light with the same vibration direction as the polarization axis of the polarizer remains.

That is, linearly polarized light. The polarized light passes through the liquid crystal cell and then exits through a polarizer (called an analyzer). In this way, whether the light passes through the analyzer depends on the polarization state of the linearly polarized light after passing through the liquid crystal cell. Thereby controlling the state of the light passing through the analyzer to realize the display.

Specifically, the liquid crystal molecules in the TN-type liquid crystal cell form a twisted structure. Under certain conditions, the polarization of the incident light will rotate along the twisting direction of the liquid crystal molecules. The long axis of the liquid crystal molecules is twisted by 90°, resulting in the optical rotation of 90°. When a certain voltage is applied to the electrodes on the two glass sheets, the liquid crystal molecules are transformed into an arrangement perpendicular to the upper and lower glass sheets, and the twisted structure disappears, resulting in The optical rotation disappears, and this electro-optic effect is called the twisted electric field effect.

For a black-on-white liquid crystal display, the upper and lower polarizers are placed orthogonally. That is, the polarization axes are perpendicular to each other, and the incident natural light becomes plane polarized light after passing through the polarizer. When no electric field is applied to the liquid crystal cell, the polarized light will be twisted along the twisted structure of the molecule by 90°, the vibration direction becomes consistent with the polarization axis of the analyzer, so it can pass through the analyzer smoothly, and the display is in a transparent state at this time, and is in a non-display state, and the driving circuit adds the driving signal voltage to the relevant electrodes that need to be displayed , the twisted structure of this part of the liquid crystal molecules disappears. Lost optical power. The polarized light from the polarizer goes directly to the analyzer without change. Because its polarization direction is perpendicular to the axis of the analyzer. Polarized light will not be able to pass through the analyzer, so that part of the electrode that passes the signal voltage will appear black, in display state.

4.3 Main technical indicators of LCD:

4.3.1 Electro-optic response characteristics:

The relative light transmittance of the liquid crystal display changes with the change of the external signal voltage, which is the electro-optic response characteristic, which is one of the most important characteristics.

4.3.2 Contrast:

The contrast of the liquid crystal display is the ratio of the relative light transmittance of the display state and the non-display state. When the contrast is ≥5, the image is clear.

4.3.3 Perspective:

The contrast ratio of LCD is related to the viewing angle (that is, the viewing angle of human eyes). The characteristic that the contrast varies with the viewing angle is called the viewing angle characteristic. Viewing angle characteristic indicator. Generally, a minimum acceptable value of contrast is determined to examine the viewing angle range where the contrast is greater than this value, and this range is called the viewing angle cone. For example, when the contrast ratio of LCD = 3 viewing angle value. Its top viewing angle is 10°, its bottom viewing angle is 40°, and its left and right viewing angles are 30°.

The viewing angle is the angle between the viewing direction and the normal of the display device. Viewing direction (best viewing angle quadrant): Twisted nematic liquid crystal displays have an optimal viewing direction, and the general front viewing angle (positive viewing angle) is determined from the θ angle of this direction.

One of the disadvantages of LCDs compared to other displays is their narrower range of viewing angles. If the product of cell thickness and liquid crystal refractive index anisotropy △n*d=0.5 micron or so, the viewing angle characteristics of the device will be greatly improved. But its manufacturing environment is more demanding.

4.3.4 Response time:

LCDs often display changing images. The reaction time of the human eye is on the order of a few milliseconds. Therefore, the response to the change of the displayed image and the change of the signal voltage should not be lower than this speed. The response time to describe the dynamic characteristics of the liquid crystal display is usually expressed by three constants, such as the delay time, rise time and fall time.

4.3.5 Power Consumption:

Power consumption is the energy consumed by LCD work, generally in the order of microwatts/square centimeter, and low power consumption is one of the biggest advantages of LCD. The power consumption of LCD depends on the display area, driving voltage and frequency, resistivity of liquid crystal, dielectric constant and cell thickness, etc. Among them, the positive resistivity of the liquid crystal is easy to drop sharply as the liquid crystal is polluted. Therefore, the proper preservation of liquid crystal is very important.

4.3.6 Temperature characteristics:

We know that liquid crystal materials only exhibit a liquid crystal state within a certain temperature range, and even within the temperature range of the liquid crystal state, changes in temperature will affect the physical parameters of the liquid crystal material. Such as viscosity, dielectric constant and elastic constant etc.

5. Raw materials used to manufacture LCDs and LCD manufacturing processes.

5.1 The raw materials used in LCD manufacturing refer to the raw materials retained in the product after the LCD is produced. Mainly include: ITO glass liquid crystal, polarizer, PI liquid, screen printing glue (printing frame glue, conductive glue), sealing glue, Ni powder, plastic gasket, etc. Generally speaking, the three main raw materials of LCD are: liquid crystal, ITO glass and polarizer. Auxiliary materials for LCD manufacturing refer to raw materials that are used in the production process and do not exist in the final product, such as: photoresist and thinner, NMP, PI thinner, BC liquid, SiO2 thinner, abrasive cloth, isopropanol, ethanol , acetone, cleaning agent, acid, alkali, etc.

5.2 The above are the raw materials we know about the use of LCD. In fact, the LCD manufacturing process and LCD production process are the processing and combination process of these raw materials. The specific process flow chart is as follows: Material preparation; Cleaning and drying; Gluing; Front baking; Exposure; Development; Scleroderma; Etching; Film removal; Coating alignment film; Pre drying and curing; Orientation; Silk screen printing; Spreading; Fitting (combination); Curing; Cutting; Filling LC; Sealing (dispensing and cementing); Cleaning; Small cracks, cleaning; Redirection (baking); Visual inspection; Electrical inspection; Cutting and pasting; Final inspection; Packaging; Warehousing

Home

Home HEM LCD

HEM LCD  Mar 23,2023

Mar 23,2023

What is the structure of LCD displays? What is LCD classified?

What is the structure of LCD displays? What is LCD classified?

Feb 27,2023

Feb 27,2023